The department of energy estimates that 40% of energy usage in buildings is due to uncontrolled air leakage. This air leakage is primarily found in your walls, floors, ceilings, and ductwork. How can LBS help you improve the comfort and energy efficiency of your home?

AEROSEAL DUCT

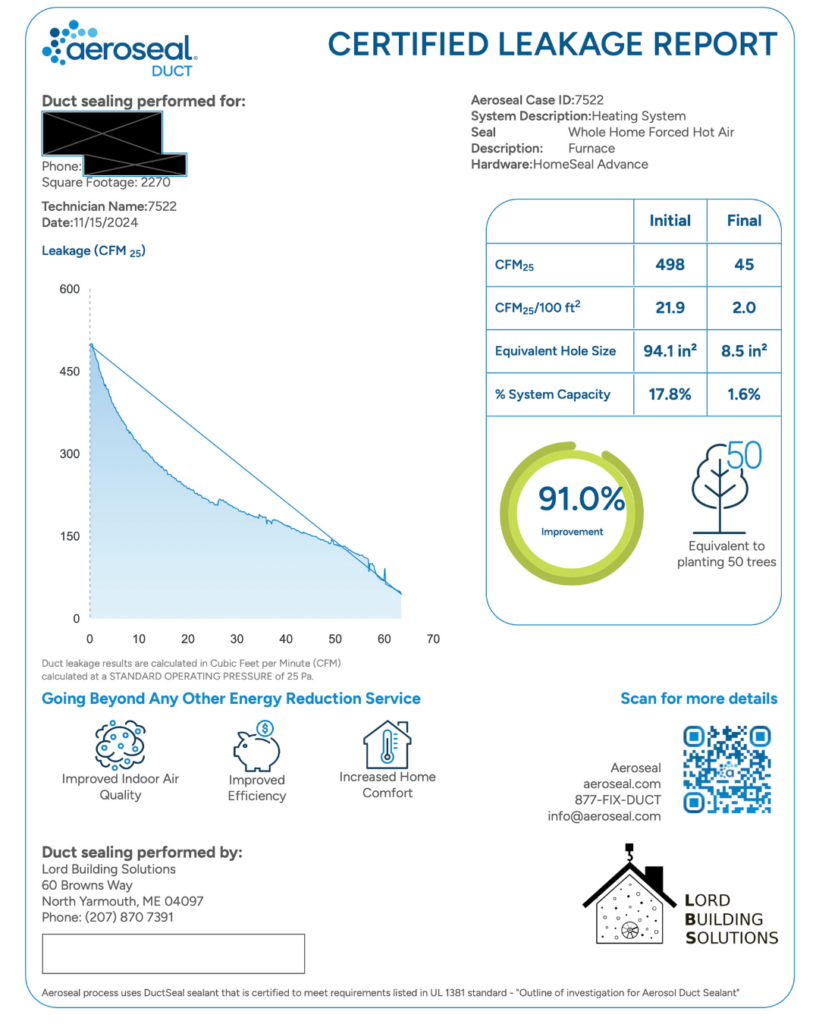

Aeroseal's duct sealing technology efficiently seals ductwork in both residential and commercial settings using a patented, non-toxic aerosol sealant. The process pressurizes duct systems, driving sealant particles precisely to leaks, sealing them from the inside out without coating the entire duct interior. Our advanced formula is very low tack, ensuring it only deposits where needed and maintains duct integrity. Monitored in real-time for coverage and effectiveness, this technology improves HVAC efficiency, air quality, and comfort. Suitable for new constructions and retrofits, it precisely meets duct sealing goals.

Step 1 - Preparation

- All supply & return registers are taped over and furnace/coils isolated from the duct system

Step 2 - Connect

- The equipment is connected to the duct system via an inlet hole or directly through a register

Step 3 - Seal

- The computer-controlled equipment automativally sprays sealant through the pressurized ductwork, only filling cracks & holes.

Step 4 - Certify

- Equipment is disconnected, any inlets are patched, and the Seal Certificate is created to verify results.

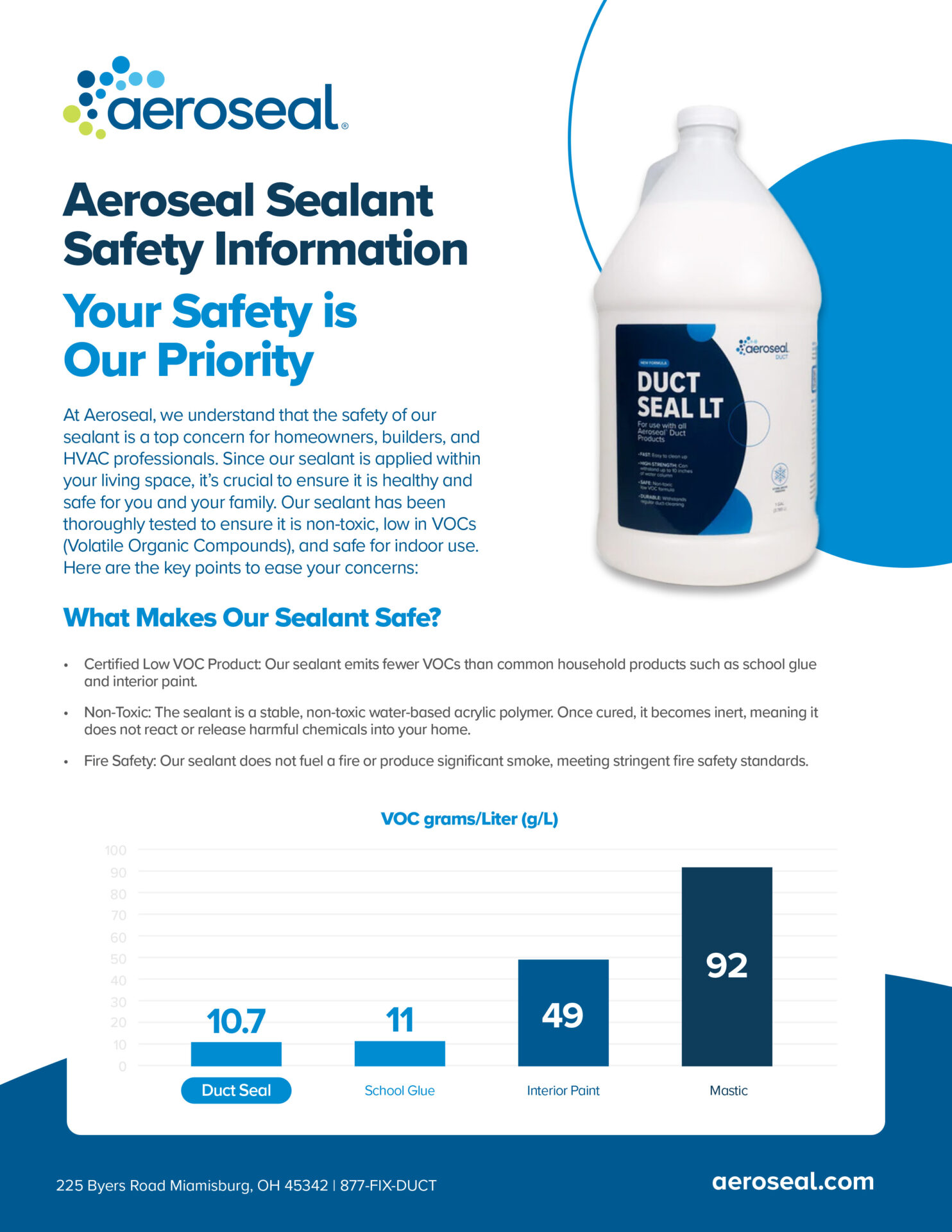

NON-TOXIC AEROSEAL DUCT SEALANT

SAFETY & HEALTH INFORMATION

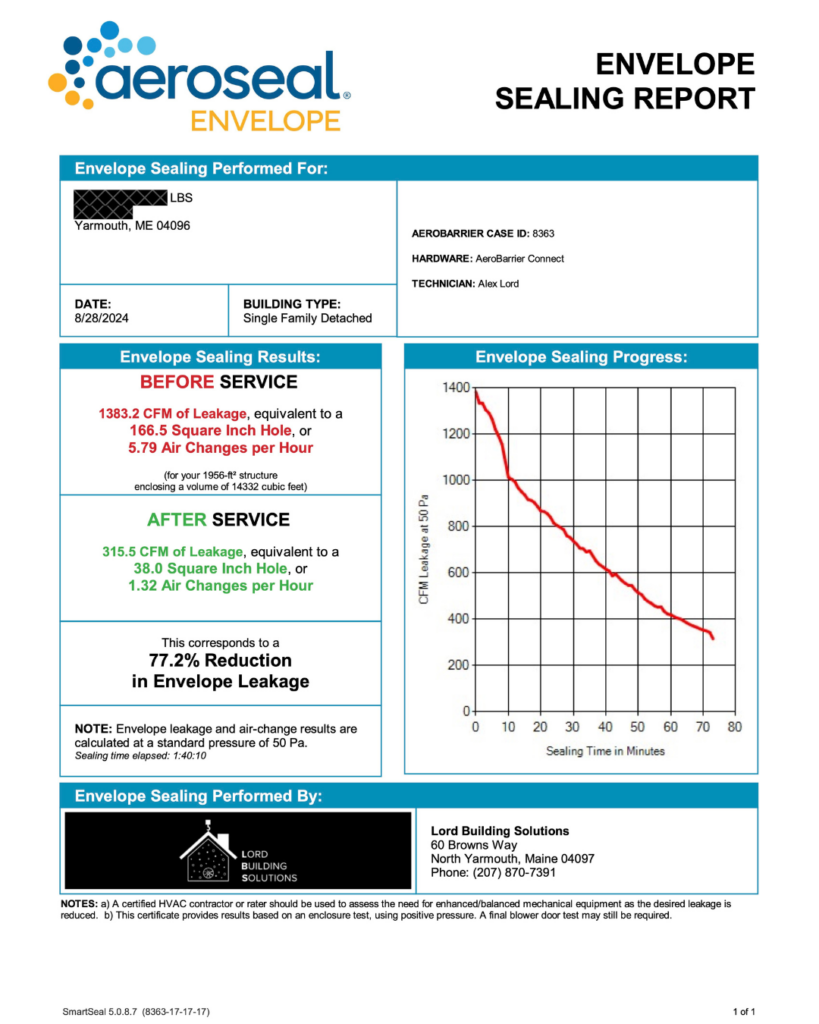

AEROSEAL ENVELOPE (AEROBARRIER)

Aeroseal’s AeroBarrier offers an advanced measurable solution for air sealing building envelopes efficiently and effectively. The AeroBarrier system pressurizes the building interior and releases an aerosol mist containing sealant particles. These particles are carried by airflow to any leaks in the building envelope, where they accumulate to gradually seal the openings. The automated air sealing process is monitored in real-time to ensure thorough coverage and optimal sealing effectiveness. AeroBarrier technology is known for its precision and ability to detect and seal even the smallest air leaks, contributing to improved energy efficiency, indoor comfort, and air quality in buildings.

Step 1 - Preparation

- Cover finished horizontal surfaces

- Cover openings that should not be sealed

- Set up equipment

Step 2 - Pressurization & Application

- Pressurize space and establish baseline leakage

- Input your targeted air tightness (air changes per hour)

- Begin injection of aerosolized AeroBarrier Sealant via Computer Controlled Software

Step 3 - Sealing & Monitoring

- Monitor sealing progress

- Track and report proegress every 60 seconds

- Verify sealing to targeted air tightness

Step 4 - Clean Up

- Generate Envelope Sealing Report

- Remove protective coverings & equipment

- Return to the building immediately after clean up has been completed

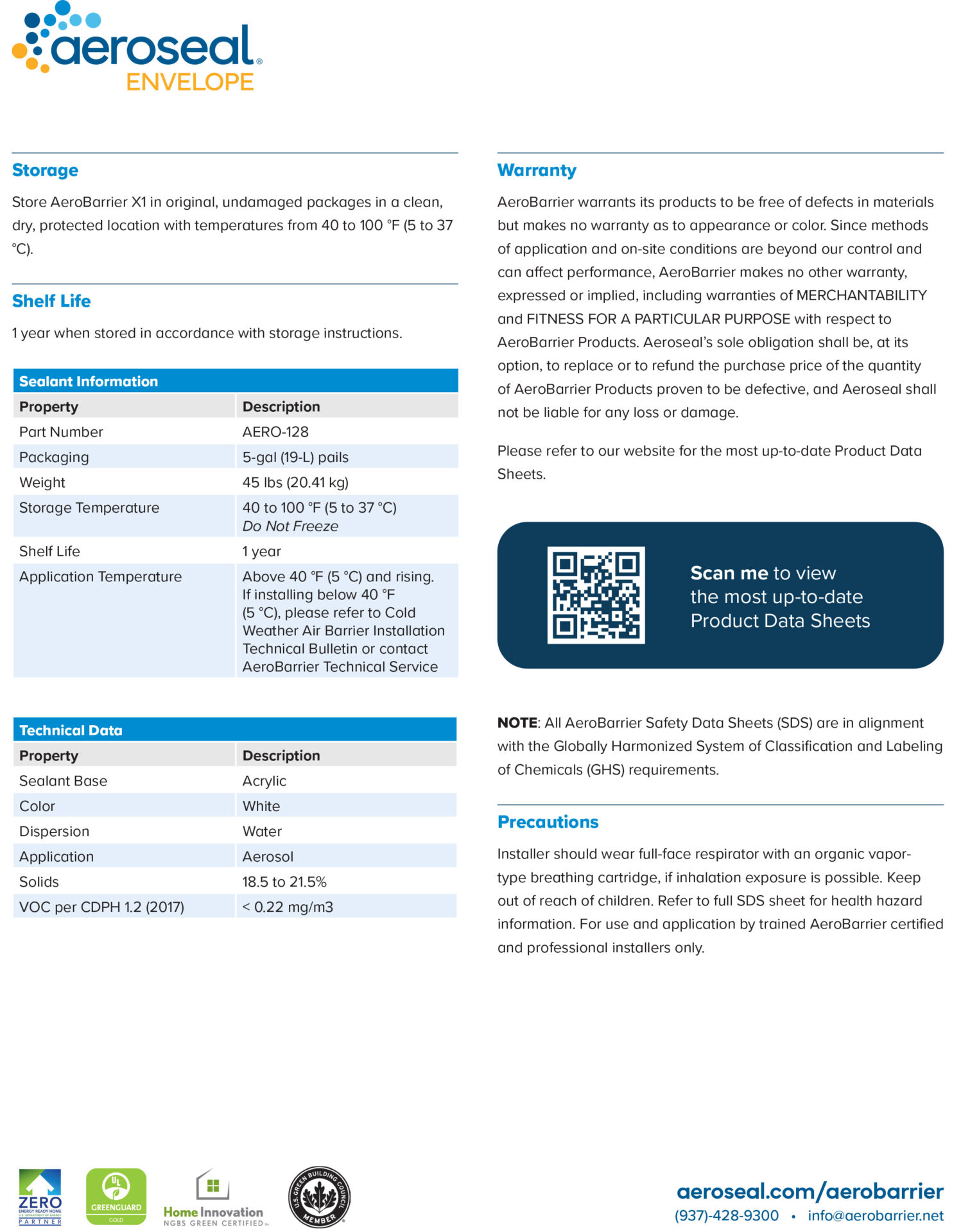

NON-TOXIC AEROSEAL ENVELOPE SEALANT SAFETY & HEALTH INFORMATION

Efficiency Maine

Weatherization Rebate Program

EFFICIENCY MAINE RESOURCES

Why air seal?

Weatherization Rebate Information

GO GREEN WITH LORD BUILDING SOLUTIONS

& AEROSEAL!